The E-coating process (electrophoretic dip coating) ensures a perfect coating quality also in case of parts with special forms and it ensures better corrosion protection. After pre-treatment parts will be moved into the EC (KTL) tank. The coating will adhere on the part surface on electromechanical way. Parts to be treated are dipped during the EC dip-coating process in waterborne paint with low solids content. Under the DC voltage field between part and counter electrode, solid parts in the EC bath will be separated on the part. Extra smooth paint coating layer arises with excellent sticking on the edge and other places. Company Knipl provides the know-how and manufacturing base for the planning and production of dip-coating systems.

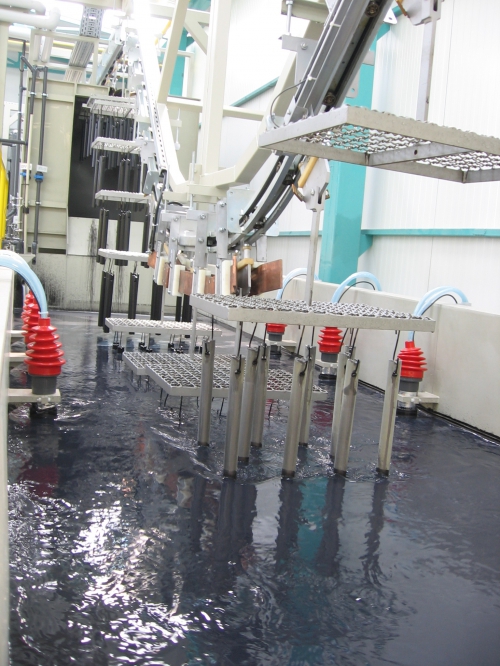

By means of racks / material moving systems and the optimal bath circulating, our plants ensure a perfect coating quality also in case of parts with special forms. Plant with tact operation means that the material moving happens by means of hoists.

These plants are suitable for coating of mass output of uniform parts. The material moving occurs with conveyor. The continuous e-coat plants can be used for dip coating as well as for the combined process of spray and dip coating.

The dip paint plant with tact operation and Power & Free material moving system is suitable for lower part quantity and mainly larger parts. It has a compact construction and the dip tanks have a smaller volume. This plant is very cost efficient due to the sinking and lifting system; other material moving units are not needed.

We build our KTL systems with well-known components. Our plants contain all needed units, which are needed for the safe and effective function: